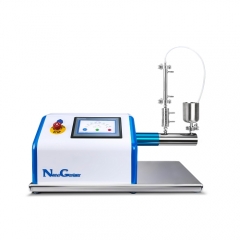

NanoGenizer Lab Homogenizer for Cell Disruption

NanoGenizer High Pressure Homogenizer for Nanomaterials

NanoGenizer, a lab-scale microfluidic high pressure homogenizer, offers effective performance on particle size reduction and cell disruption. It utilizes interaction high-pressure microfluidic jet technology, and equipped with highly modular power and processing units. NanoGenizer is suitable for rare and valuable samples because of its minimum dead volume design and its continuous flow rate, which enables it to process up to 120 mL/min. With successful applications in various nanotechnology settings, the NanoGenizer has gained increasing recognition due to its notable shear rate, excellent repeatability, and guaranteed scalability.

NanoGenizer provides efficient solutions for various nanomaterials, including: liposomes, nano-emulsions, nano-crystals, micelles, lipid nanoparticles, cosmetic nano-encapsulation materials, nano-particle dispersion, graphene, carbon nanotube, and more. As more organizations recognize this, NanoGenizer is becoming an essential high pressure homogenizer for laboratories working on high-end nanomaterial preparation.

NanoGenizer provides efficient solutions for various nanomaterials, including: liposomes, nano-emulsions, nano-crystals, micelles, lipid nanoparticles, cosmetic nano-encapsulation materials, nano-particle dispersion, graphene, carbon nanotube, and more. As more organizations recognize this, NanoGenizer is becoming an essential high pressure homogenizer for laboratories working on high-end nanomaterial preparation.

Figure 1. NanoGenizer microfluidic jet high pressure homogenizer

Core Technology: Interaction Chamber with Microfluidic Jet

NanoGenizer can be divided into a power unit (including the power system, control system, and high-pressure pump system) and a processing unit (including the microfluidic diamond interaction chamber, material inlet and outlet, and heat exchanger). The diamond interaction chamber is a reaction component with a specially-designed fix geometry, where high pressure, high speed micro-jets occur and samples are processed. After being pressurized and accelerated by the intensifier, the sample’s micro-jet can reach speeds of 1,000 m/s, faster than the speed of sound (340 m/s). When the high-speed bullet-type micro-jet passes through the diamond interaction chamber’s micro-channels, it undergoes complex physical effects, such as high-frequency shearing, high-energy impact, cavitation and pressure drop, and more. After that, the material is homogenized and nano-sized.

The diamond interaction chamber is the core area where the high-speed micro-jet, high-shear, high-energy collision, and other effects occur. It has fixed Y- or Z-shaped diamond micro-channels inside, which guarantees a consistent effect: accurate and repeatable particle size distribution.

Figure 2. Schematic of the internal structure of the DIXC

Figure 3. Single-slotted interaction chamber with cooling system

Figure 3. Single-slotted interaction chamber with cooling system

Features of the NanoGenizer High Pressure Homogenizer

High Shear Rate

After being pressurized by the power unit, the liquid or solid-liquid mixture sample’s micro-jet can reach speeds up to 1,000 m/s inside the diamond interaction chamber (DIXC). The minimum dimension of the inside of the DIXC can be as small as 50 μm. As shown in Figure 4, the NanoGenizer’s shear rate is the highest among comparable technologies.

Figure 4. Shear rates of comparable homogenizing technologies

The NanoGenizer high pressure homogenizer’s shearing force on the material is unmatched by conventional homogenizers or other homogenizing equipment.

Fixed Internal Structure and Consistent Reaction Pressure

Figure 5. Single-slotted Y-type microfluidic diamond interaction chamber

Figure 6. Single-slotted Z-type microfluidic diamond interaction chamber

The diamond interaction chamber has a fixed internal shape (Figures 5 and 6) and does not move with pressure changes. When the sample passes through the DIXC, the applied pressure is at a constant peak during each cycle’s process (see the blue curve in Figure 7). However, the traditional homogenizing valve has a dynamically adjustable structure. The pressure of the material changes dynamically when it passes through a conventional homogenizer’s valve, which operates at peak pressures for mere moments of each cycle (the black curve in Figure 7). The particle size of the material processed by the microfluidic diamond interaction chamber is reduced efficiently, and the distribution is more uniform than can be achieved with a traditional homogenizing valve.

Figure 7. Pressure curve during homogenization process

Interaction Effect

The design of the Y-type DIXC takes full advantage of the interaction collision of the materials themselves. The instantaneous relative velocity of the two jets is doubled, resulting in an explosion effect. The collision between the materials greatly reduces the materials’ wear and shear to the interaction chamber, prolonging the chamber’s service life and avoiding the risk of stainless steel particles falling off. The patented DIXC-RT with cooling function (see Figure 3) protects the bioactivity of the samples.

Guaranteed Scalability

Figure 8. Multi-slotted Y-type microfluidic diamond interaction chamber

Figure 9. Multi-slotted Z-type microfluidic diamond interaction chamber

Figure 9. Multi-slotted Z-type microfluidic diamond interaction chamber

The single-slotted DIXC (shown in Figure 2 and Figure 3) is suitable for lab-scale high pressure homogenization equipment. The multi-slotted DIXC (shown in Figure 8 and Figure 9) is composed of multiple diamond micro-channels copied in parallel, ensuring the treatment effect’s consistency. The increased number of channels also allows for larger volumetric flow rate.

Genizer LLC is one of two companies in the world that supplies high pressure homogenizers equipped with original microfluidic diamond interaction chambers. In recent years, Genizer’s microfluidic diamond interaction chambers have been equipped by more and more homogenizer manufacturer.

Easy to Operate and Intelligent

The highly modular and integrated control design of NanoGenizer makes it extremely simple to install and operate. Operators can complete routine operations by clicking the three buttons—"pressure rate,” “start,” and “stop”—on the touch screen. Customers find the equipment simple to operate: They only need to set a pressure on the screen and then click to start or stop. There is no need to screw the valve forcefully or waste any sample to adjust the pressure. To process a particularly small volume, you can set the sample volume processed by one stroke, the stroke cycle times, and the automatic stop time on the setup interface. Compared with other high pressure equipment, the NanoGenizer’s operation is elegant and efficient.

Figure 10. Operation interface of the NanoGenizer

Small Minimum Sample

NanoGenizer’s highly modular design enables simple installation and maintenance. The dead volume is no more than 1 mL, far below the dead volume of other high pressure homogenizers, which is typically more than 10 mL. Therefore, when a 10 mL sample is processed in traditional homogenizers, it is almost impossible get product from the outlet. NanoGenizer's modular pipeline design can achieve a minimum single processing volume of 5 mL by setting the volume autonomously, making it the best equipment option for preparing and developing rare, costly samples. NanoGenizer’s continuous flow rate is 7 L/h, suitable for conventional small batches.

Software and Hardware Options

Temperature Control: Jacketed interaction Chamber; jacketed inlet cylinder; 3D heat exchanger

Suspension Preparation: Hollow magnetic stirrer

Corrosion Resistance: Titanium cylinder option

Precision Sampling: Precision sampling as accurate as 0.1 mL (e.g., 10.0mL, 10.1mL, and 10.2mL sampling are all possible)

Ports: Data log, USB port, and multi-sensor ports for temperature and pressure

Scientific researchers who have used NanoGenizer are impressed by its high processing efficiency, easy operation, and intelligent control. NanoGenizer is currently the one of the most selected homogenizers for nanomaterials in the world.

NanoGenizer’s highly modular design enables simple installation and maintenance. The dead volume is no more than 1 mL, far below the dead volume of other high pressure homogenizers, which is typically more than 10 mL. Therefore, when a 10 mL sample is processed in traditional homogenizers, it is almost impossible get product from the outlet. NanoGenizer's modular pipeline design can achieve a minimum single processing volume of 5 mL by setting the volume autonomously, making it the best equipment option for preparing and developing rare, costly samples. NanoGenizer’s continuous flow rate is 7 L/h, suitable for conventional small batches.

Software and Hardware Options

Temperature Control: Jacketed interaction Chamber; jacketed inlet cylinder; 3D heat exchanger

Suspension Preparation: Hollow magnetic stirrer

Corrosion Resistance: Titanium cylinder option

Precision Sampling: Precision sampling as accurate as 0.1 mL (e.g., 10.0mL, 10.1mL, and 10.2mL sampling are all possible)

Ports: Data log, USB port, and multi-sensor ports for temperature and pressure

Scientific researchers who have used NanoGenizer are impressed by its high processing efficiency, easy operation, and intelligent control. NanoGenizer is currently the one of the most selected homogenizers for nanomaterials in the world.

Figure 11. Applications of NanoGenizer for nanomaterials

USD

USD

949-932-0294 Los Angeles

949-932-0294 Los Angeles  Nano@Genizer.com

Nano@Genizer.com