Description:

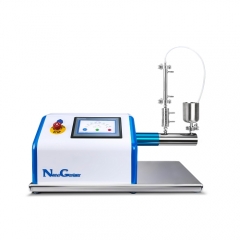

Laboratory Quad-Pump up to 30,000 psi with concept testing of parallel and series flow direction.

Application:

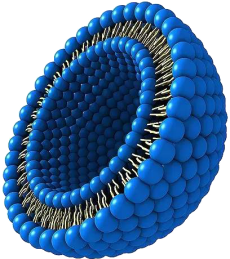

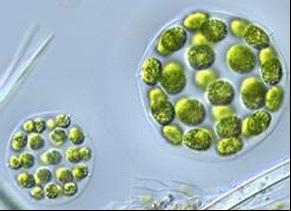

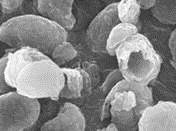

Nanodispersions, nanoemulsions and nanotube

Cell disruption

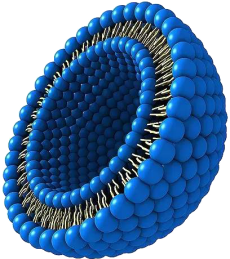

Micro/nanoencapsulation in polymers, liposomes and oils

Solid dispersion and suspension, deagglomeration

Performance:

Energy efficient, 1/2 energy loss of the most homogenizers

Small (integrated design delivers the light weight and small dimensions)

Smart (programming control systems confer diligent functions: auto stop with time/volume)

Silent (noiseless performance)

Strong (6-27L/hr)

CE compliant and RoHs compliant

| Specification |

| Catalog No. |

NanoGenizer-Quad |

| Flow Rate |

6-27L/hr |

| Min. Sample |

5mL |

| Max. Pressure |

30,000psi |

| Dimensions(cm) |

92 × 69 × 40 |

| Weight |

117 kg (258 lbs) |

| Max. Temp. |

80ºC (176ºF) |

| Power |

220V |

| Cleaning |

Flush to clean |

| Application |

Nano emulsion, fat emulsion, liposome, cell disruption, nano dispersion, deagglomeration |

| Features |

Digital display of pressure or pressure gauge |

| |

| Standard Features |

| Parts |

Y-type diamond interaction chamber with cooling option |

| Control System |

High pressure programming control systems: touch screen, speed control, auto stop control by volume, time, pressure or temperature, display of flow rate and time, overload protection |

| Pressure Gauge |

Digital display on the touch screen |

| Inlet Type |

Tri-clamp |

| Outlet Type |

Tri-clamp |

| Inlet Reservoir |

500mL S/S cylinder |

| Outlet Reservoir |

Plastic hose |

| Product Material |

316L stainless steel, tungsten carbide, viton, teflon |

| Material Standard |

Sanitary grade, FDA, GMP |

| Warranty |

1 year against any manufacturing defects |

| |

| Option Features |

| Parts |

High pressure extruders, homogenizing valves, heat exchanger |

| Control System |

Mechanical control: speed, start, stop controls |

| Detector |

Pressure gauge, pressure transducer up to 8 optional, temperature transducer up to 8 optional |

| Outlet Type |

Tri-clamp or luer |

| Inlet Reservoir |

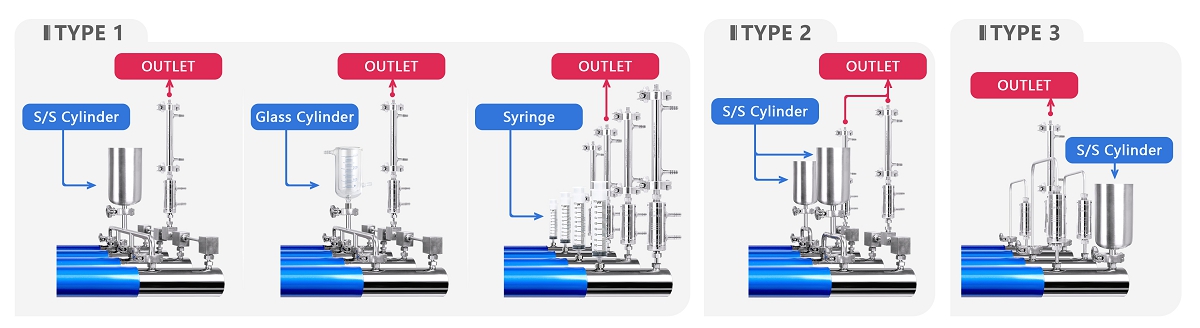

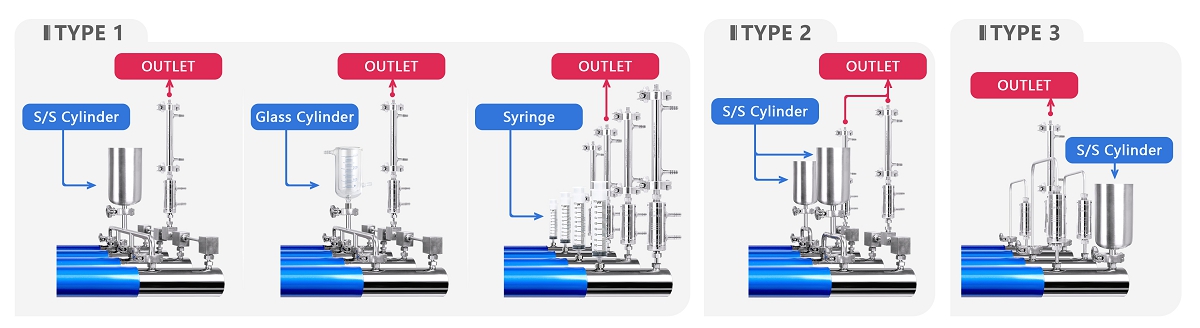

10mL, 20mL, 50mL, 100mL, 200mL syringe, S/S cylinder, jacketed glass cylinder or online |

| Outlet Reservoir |

10mL, 20mL, 50mL, 100mL, 200mL, syringe, S/S cylinder, jacketed glass cylinder or online |

| Cylinder |

Titanium high pressure cylinder (resistant to strong acid and base) |

| |

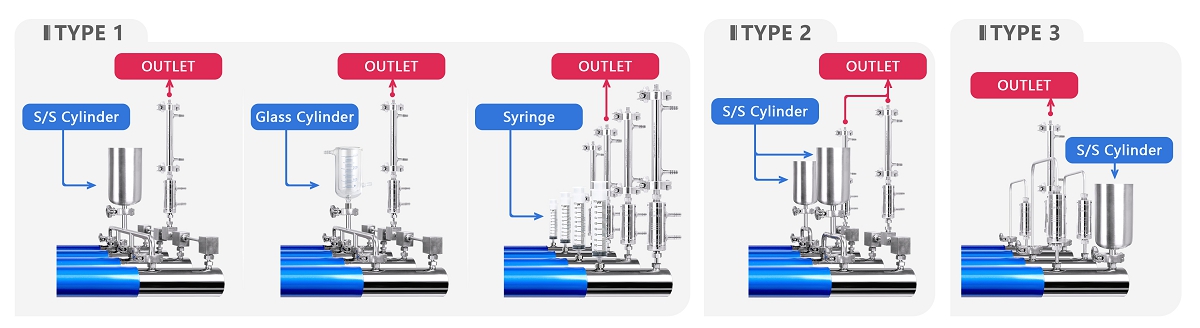

Varieties of Inlet and Outlet for NanoGenizer-Quad

Inlet: syringe; open container; stainless steel cylinder

Outlet: syringe; open container; stainless steel cylinder

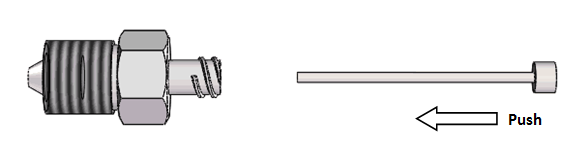

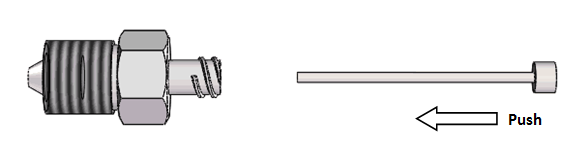

Disassemble the seal

Assemble the seal

Assemble the seal

Troubleshooting:

Our design has minimized the occurrence of air-blocking, chamber-blocking and overload.

However, the improper operation of the homogenizer can still induce errors and cause damage to the homogenizer.

Air Blocking

Symptom: there is no pressure and no sucking from inlet

Prevention: do not run with empty inlet

Reason: there is air inside the pump

Solutions:

1) In the customer setup, press the "Degas" button.

2) Running 50mL water with 50% speed

3) Push the ball into the inlet valve with a pin

Chamber Blocking

Symptom: overload of the pressure

Prevention: pre-treat the sample carefully; reduce the speed

Reason: there are aggregates or particles in the sample; too high a speed

Solutions:

1) Reverse flow the outlet valve with 100mL water with low speed

2) Reverse flow the chamber with water from low to high speed

Overload

Solutions:

1) Reduce the speed and close the power, wait 30 sec and restart

2) Wash with water or solvent

3) Run with clean and homo-disperse sample

No Response

Symptom: the equipment does not respond when click the “Start” button on the touch screen

Solutions:

1)Turn off the power supply and wait for 30 sec to restart

2) If there is still no response, please check the power input. The power supply of the equipment is 220V. When the external power supply is 110V, a power converter shall be used. And its INPUT port should connect to 110V while the OUTPUT port connect to 220V

Air blocking rarely causes damage to the NanoGenizer; however, the chamber blocking is harmful to the pump because of overloaded pressure in an instant.

1) Pretreat the sample carefully, and always use a clean and homo-disperse sample

2) Adjust the pressure from low to high

3) For safety, do not point the inlet or outlet of high pressure devices and equipment supplied by Genizer, including high pressure homogenizer, extruder, interaction chamber and valve, to any personnel or object that may affect safety or induce property loss.

Tips:

For facilitating the user applications, the two ports in the high pressure cylinder of the NanoGenizer are exchangeable for inlet and outlet.

Pressure and chamber selection for various applications with NanoGenizer

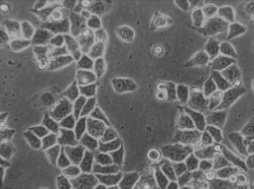

| Cells |

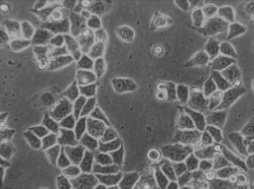

Mammalian cell

|

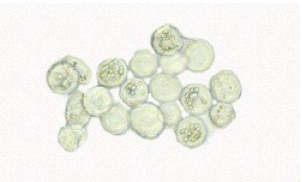

Insect cell |

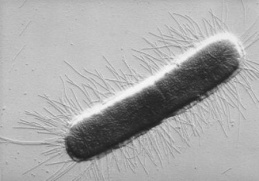

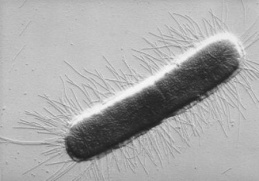

Bacteria cell |

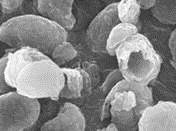

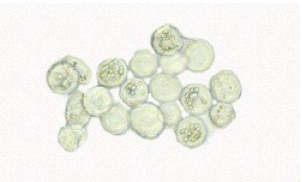

Yeast cell |

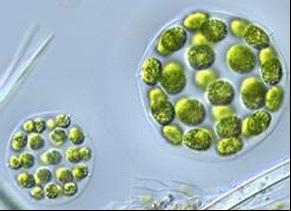

Algae cell |

Spore

|

| Sample |

CHO|Hela |

Sf9|Sf21|H5 |

E. Coli |

Yeast |

Green algae |

Ganoderma |

| Pressure |

600-800bar 8500-11500psi |

600-1000bar 8500-14500psi |

800-1000bar 11500-14500psi |

1200-1400bar 17500-20000psi |

1200-1500bar 7500-21500psi |

1300-1600bar 18500-23000psi |

| Chamber |

F20Y, F20Y-RT |

F20Y, F20Y-RT |

F20Y, F20Y-RT |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

| Emulsions |

Oil in water emulsions

|

Water in oil emulsions |

Oil emulsion |

Food |

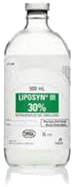

Liposome (o/w) |

Liposome (w/o)

|

| Sample |

Fat emulsion |

Cosmetics |

Fuel |

Milk |

DOX |

DNA|lipopolyplex |

| Pressure |

~20,000psi |

~10,000psi |

~20,000psi |

~10,000psi |

~20,000psi |

~8,000psi |

| Chamber |

F20Y, F12Y |

F20Y |

F20Y, F12Y |

F20Y |

F20Y, F12Y |

F20Y |

| Dispersions |

Pigments

|

Creams |

Battery |

Particle aggregation |

Graphene |

Nanotubes

|

| Sample |

Inks, Coatings |

Creams |

Lithium/Solar cell |

Nano fibril |

Graphene |

Carbon Nanotubes |

| Pressure |

~25,000psi |

~20,000psi |

~20,000psi |

~25,000psi |

~20,000psi |

~20,000psi |

| Chamber |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

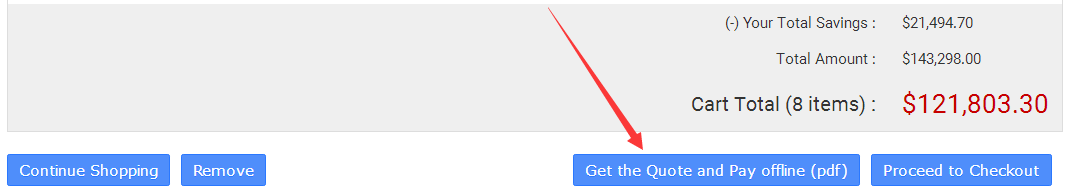

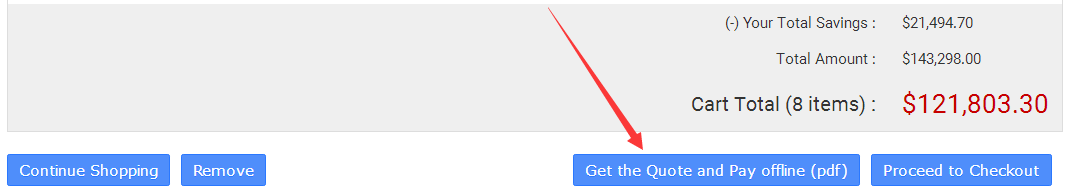

1. Order the unit from your local agent (recommended)

2. Add the item to the cart, get an online quote from our website and confirm the order and payment accordingly (recommended and quick)

3. Email us to get a quote

4. Order and pay online from the website if the total amount is under $2,500.00.

USD

USD

949-932-0294 Los Angeles

949-932-0294 Los Angeles  Nano@Genizer.com

Nano@Genizer.com